|

EMH is a member of Crane Manufacturers Association of America (CMAA). CMAA is a division of Material Handling Industry of America (MHIA). EMH is certified to ISO 9001:2008 standards for design, manufacturing, installation, and servicing of overhead cranes. |

- Hoist design conforms to all applicable national and local standard standards.

- You are dealing with an organization that continually reviews its management processes and meets internationally accepted standards.

|

Inverter Controls |

Infinitely variable speed control of all motions. Initial start shock is minimized.Up to 50% overspeed capability.Reduced electrical current inrush.Closed loop encoder provides motor feedback to the controller. |

- Lifting and lowering can be executed safely and precisely.

- Prolonged motor life.

- Increased productivity.

- Well suited for Class D and E applications.

- Reduced brake wear.

- Eliminates the need for a mechanical load brake.

|

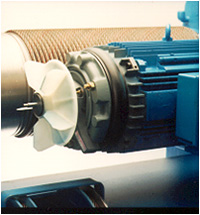

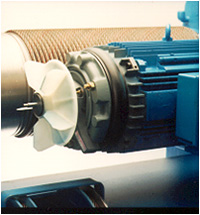

Severe Demand Hoist Motors |

EMH hoist motors are designed and built to meet the most exacting demands of hoisting service. They are well suited for the frequent reversal and high torque of heavy-duty crane applications. The inverter-duty motor is equipped with an encoder for closed loop speed regulation. This compact feedback mechanism is directly coupled to the motor. |

-

Maintenance free.

-

Energy efficient.

-

Logevity.

|

Encoder |

Provides feedback from motor to inverter control. Standard dynamic braking. |

- Smooth acceleration and deceleration with simple 2-step button control.

- Precision handling at the slowest speeds without overheating.

- Mechanical load brake not needed.

|

DC Rectified Disc Brakes |

A DC rectified magnet actuated disc brake is automatically applied in the event of a power failure. These self-compensating and virtually maintenance free brakes are provided with asbestos-free, non-polluting linings. |

- Operate millions of times without adjustment.

- Reduced service requirements.

- Longevity.

|

Gear Box |

Unibody design allows many combinations of ratios, speeds and capacities. AGMA Class 13 Standards. Hardened and polished helical gearing.Readily accessible bearings and shafts. |

- Adaptable for a wide range of applications.

- Smooth, quiet operation.

- Long service life.

- Easy maintenance.

|

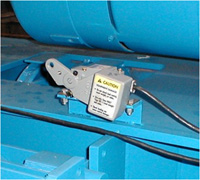

Geared Limit Switch |

One geared limit switch with one lower and two upper limits is standard.Easily adjustable, the switch brings the load hook to a positive stop at any desired position in both lifting and lowering directions. |

- Safe operation.

- Eliminate slack cable conditions.

- Prevent rope from unraveling.

- Prevents two-blocking occurrences.

|

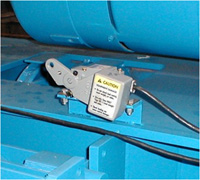

Weight Operated Limit Switch |

Meets OSHA and CMAA requirements. Safety feature used in addition to gear limit switch. |

- Protects bottom block and load at upper limit.

|

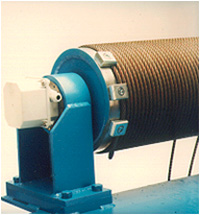

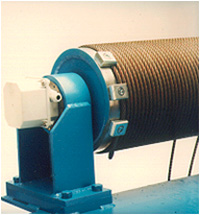

Wire Rope and Drum |

Drum is of seamless steel tube construction with precision-machined grooves. At least two wraps of rope remain on the drum when the hook is fully lowered. Our rope is of IWRC (Independent Wire Rope Core) construction for excellent strength and crush resistance.Multiple reeving configurations available. |

- Longer rope life.

- Requires less maintenance.

- Prevents rope from being unbraided and cut.

- Protects operator from injury.

- Customized for your application.

|

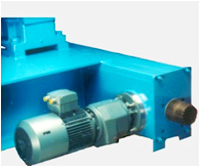

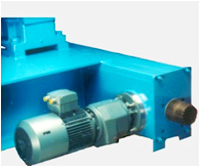

Trolley Drive |

Heavy duty single speed squirrel cage design. Variable Frequency Drive (inverter) controls. Direct drive with splined output shaft.Class F insulation.Large surface cooling fins for excellent heat dissipation. |

- Reliable, economical.

- Infinitely variable speed.

- No open gears, pinions or couplings to lubricate.

- Extended motor life.

|

Wheels |

Trolley wheels are rolled or forged steel. Wheels are machined and hardened to protect both the runway rails and the wheels from wear. Our wheel design is unlike any other in the industry. Simple yet rugged, it allows quick and easy wheel removal without special tools. There is no axle to undress.Lifetime lubricated sealed bearings. |

- Years of trouble free service.

- Long life and high overload capacity.

- No special tools or technicians required for wheel removal.

- Smooth and quiet operating characteristics with the high dampening effect of cast wheels.

|