This single leg, double girder gantry has a pass-through cantilever that allows hoist movement beyond the wall on the left. A fully enclosed cab controls all crane functions.

Several EMH cranes are used at a Pennsylvania manufacturer of aluminum structural plate for the highway construction industry. The cranes include a 12.5 ton double girder crane with a coil handling device, a 3.5 ton single girder crane with a sheet lifter, and a jib crane with a chain hoist and air vacuum device.

A double leg gantry with torsion box girder construction in a steel facility is shown above. Note the use of a saddle trolley hoist to maximize lift and minimize overall crane height.

Four single girder cranes at a Midwestern mold facility are shown here.

Monobox construction allows a 95 foot span on these ten-ton single girder cranes. Spans up to 120 feet are possible with this design.

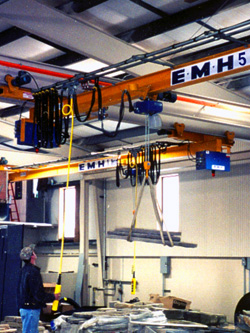

This installation at a manufacturer of roll forming equipment consists of 15 structural girder cranes with capacities from 1/2 to 5 tons. There are five bridge crane runways, with lengths varying from 70 to 250 feet. Nearly all of the cranes are used in workstation areas.

A group of two, three and five ton under running cranes provides ergonomic handling of small loads at a stone fabrication plant.

This double girder crane features box girder construction in a high heat application over a furnace. Hoist, trolley, and bridge with radio controlled Variable Frequency Drive and back-up push-button station.